ASH sequencing batch reactor

The Alfa Laval ASH Sequencing Batch Reactor (SBR) is an advanced biological wastewater treatment technology engineered for high performance and reliability. Using the activated sludge process in a sequential batch operation, it meets the most stringent effluent standards and offers exceptional flexibility for communities and industries with decant rates exceeding 25,000 gallons per minute (gpm).

Experience the all-in-one sequencing batch reactor solution for municipal and industrial wastewater treatment

- Simple robust design where all biological wastewater treatment process steps occur in the same tank

- Integrating all key stages—anaerobic, anoxic, aerobic and sedimentation—into one reactor maximizes efficiency, reduces footprint and reduces cost

- Ideal for municipal and industrial wastewater requiring consistent effluent quality under variable flows and loads

- Advanced automation and process control simplify operations, requiring less manpower

- Easy to retrofit into existing plants and earthen lagoons, or available in a package plant configuration

Benefits of SBR wastewater treatment for variable flows and loads

The sequential batch reactor process is suitable for treating all types of biodegradable wastewater, removing biochemical oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), as well as key nutrients like nitrogen and phosphorus. It provides optimized control of the SBR wastewater treatment process with advanced automation and flexibility. Unlike conventional systems, this sequencing batch reactor solution integrates all activated sludge functions into a single reactor, eliminating the need for separate basins for anaerobic, anoxic, cyclic aerobic, and sedimentation stages.

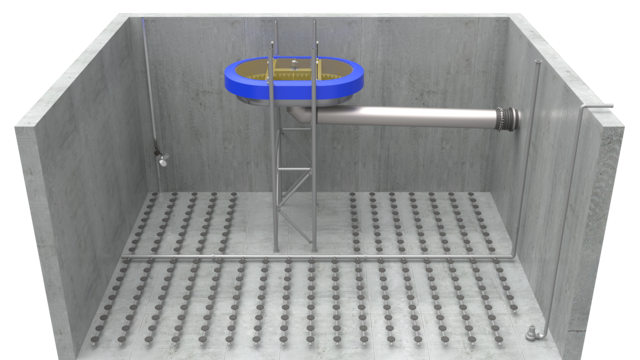

Especially suited for applications where influent flow and organic loads vary and effluent requirements are stringent, this all-in-one solution of sequencing batch reactors comes complete with floating decanters, blowers, a diffused aeration system, mixers, waste sludge pumps, motorized influent and air control valves, plus full instrumentation and a process control center. Engineered for flexibility, it fits numerous basin geometries and is ideal for both new installations and retrofits of existing basins or lagoons.

What is sequencing batch reactor wastewater treatment?

The SBR wastewater treatment process is a type of activated sludge system used primarily in municipal and industrial wastewater treatment, treating wastewater in batches through a series of cycles automatically adjusted to optimize treatment based on actual flow rates to the process:

- Static Fill – Wastewater enters the tank without mixing or aeration.

- React Fill – Wastewater continues to fill while aeration and mixing begin.

- React Phase – Biological treatment occurs as microorganisms break down pollutants.

- Settling – Aeration stops, allowing solids to settle under perfectly quiescent conditions.

- Decanting – The clarified treated water is removed at a constant flow rate throughout the cycle.

- Sludge Wasting – Excess sludge is removed from the system.

Aeration and mixing are automatically controlled during the react cycles (React Fill and React Phase) to ensure the desired effluent quality is achieved. This includes advanced nutrient removal, specifically targeting nitrogen (N) and phosphorus (P).

How do sequencing batch reactors work?

The Alfa Laval ASH sequencing batch reactor brings together the key elements of advanced activated sludge technology including anaerobic, anoxic, cyclic aerobic, and sedimentation processes into a single automated reactor, cycling between each processing step to ensure that the time for each step is optimized.

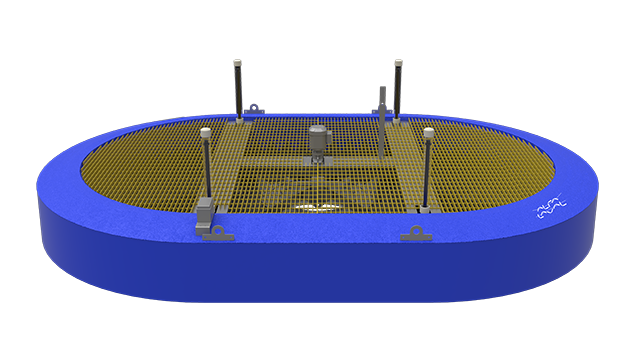

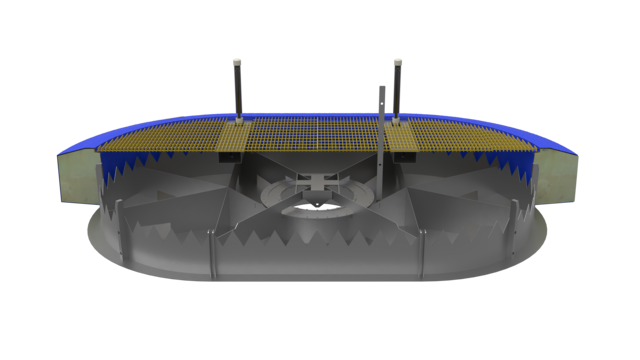

The core of the system is a floating decanter, a leading technology for constant rate decanting for the best effluent quality and optimization of downstream processes. Constant rate decanting from the top water level to the bottom water level is achieved by the lowering of a circular and/or peripheral V-notched weir. The weir is stopped at a depth that produces the target decant flow rate. Once the target rate is achieved, the weir is stopped at that point and the head over weir principal ensures that this rate is maintained from top water level to bottom.

Features that make a difference in SBR wastewater treatment process

The Alfa Laval ASH Floating Decanter employs a depth adjustable V-notch weir to precisely decant at a target rate. This prevents disturbance of settled sludge resulting in the best possible effluent quality.

The decant flow is stopped using a robust drive mechanism that raises the circular V-notch weir above the water level. No special underwater seals or valves are required.

The fiberglass encased high density foam flotation collar prevents both the accumulation of solids and the withdrawal of surface scum at the weir.

The Alfa Laval SBR System is controlled by a flow proportional control system that continuously monitors the influent flow rate to the sequencing batch reactor(s) to ensure that optimum treatment time is provided for each processing step.

Since no motorized effluent decant valve is required, installation is easier and less complicated. The floating decanter can also be purchased as a stand-alone product for managing the decant needs in various basins and lagoons including aerobic digesters.

Case stories with sequential batch reactor wastewater solutions

Let us help you

One of the Alfa Laval strengths is our process expertise, and we are a click away to provide operational support for your activated sludge process.